Warning

You are reading an old version of this documentation. If you want up-to-date information, please have a look at 2025.11 .Mounting interfaces

To guarantee a proper behavior of the Asycube a tight fastening to a solid underground is necessary. The following holes in the base plate of the different Asycube can be used to fix it mechanically.

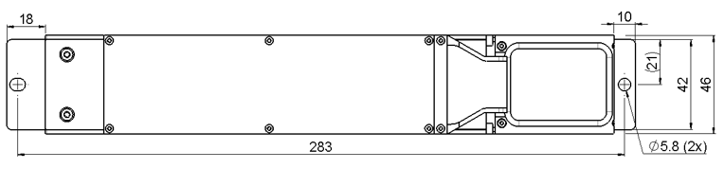

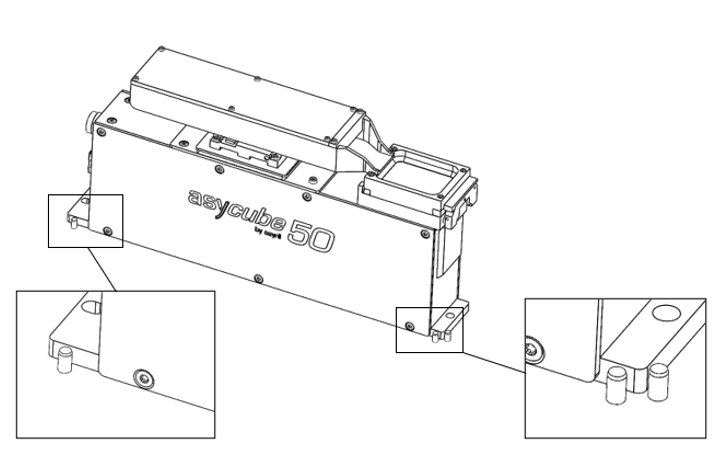

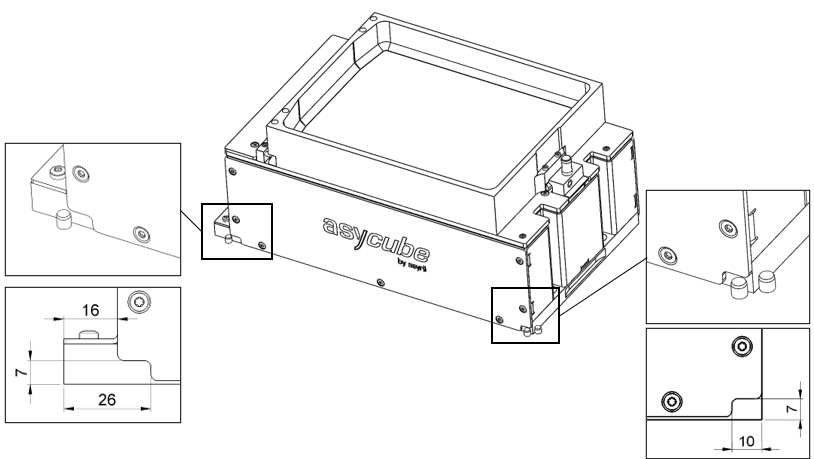

Fig. 15 Mounting interface of the Asycube 50

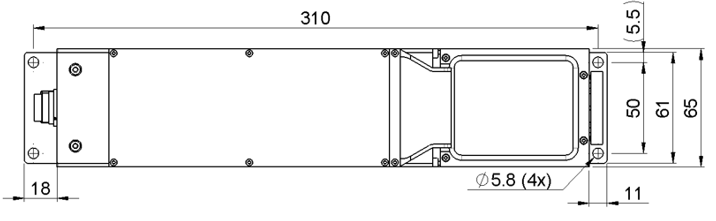

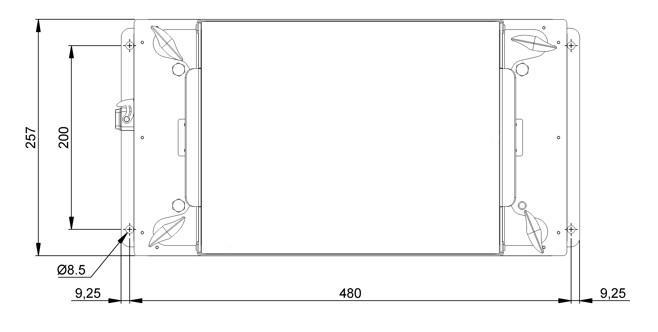

Fig. 16 Mounting interface of the Asycube 80

Repeatable positioning of the Asycube can be done by using positioning pins (possible on both sides).

Tip

Refer to section Mechanical integration to get more information.

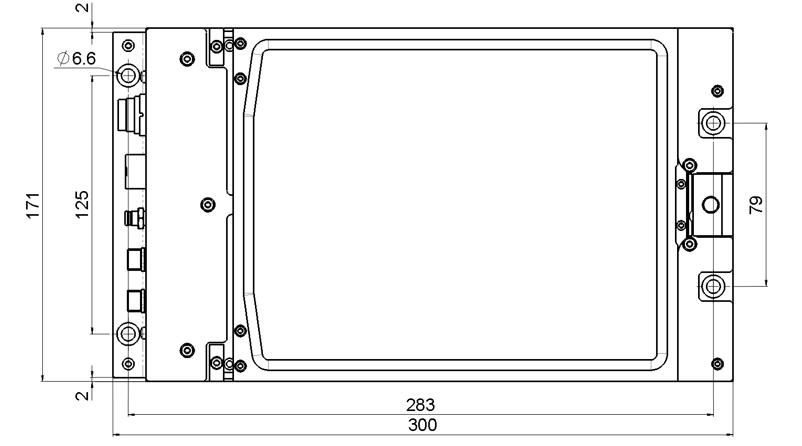

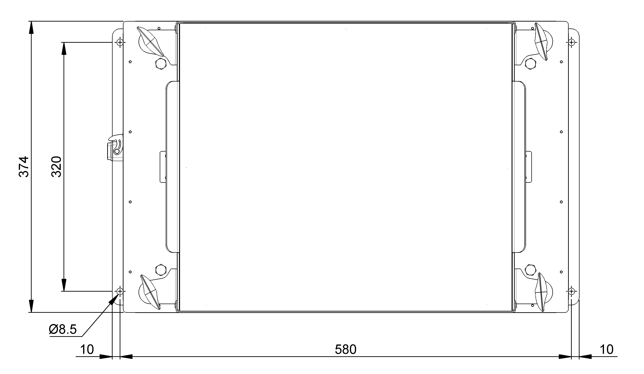

Fig. 17 Mounting interface of the Asycube 240

Repeatable positioning of the Asycube can be done by using positioning pins (possible on both sides).

Tip

Refer to section Mechanical integration to get more information.

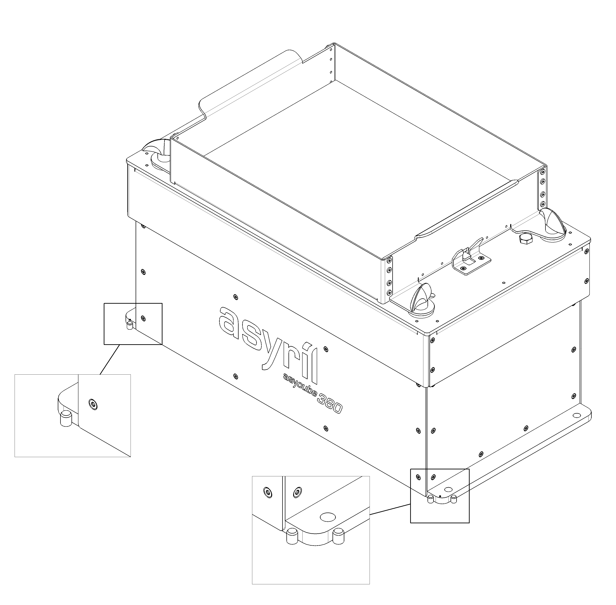

Fig. 18 Mounting interface of the Asycube 380

Fig. 19 Mounting interface of the Asycube 530

Repeatable positioning of the Asycube can be done by using positioning pins (possible on both sides).

Tip

Refer to section Mechanical integration to get more information.

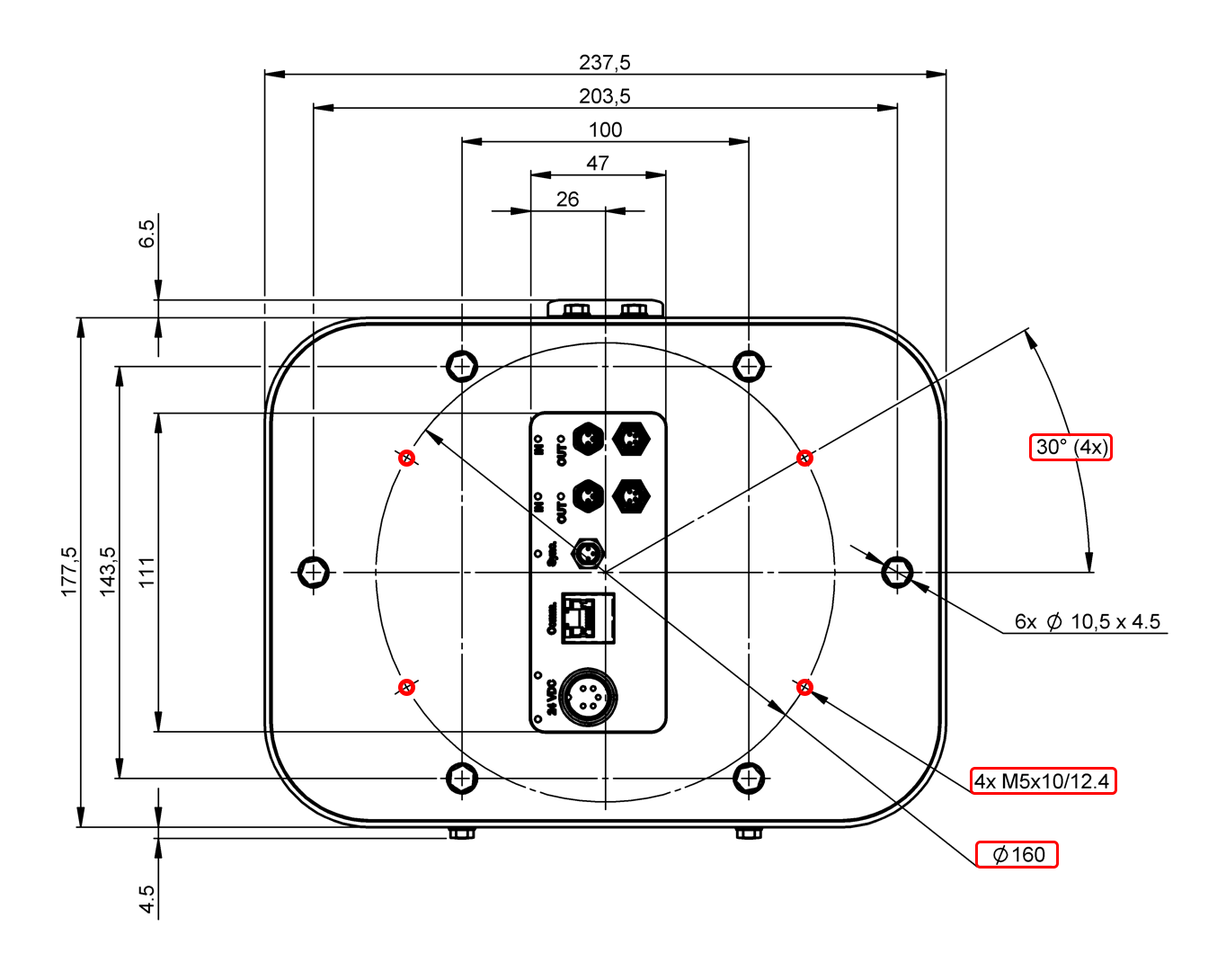

The fixation holes of the Asycube Clean 230 are highlighted in red in Fig. 20

Fig. 20 Mounting interface of the Asycube Clean 230

Important

Do not remove any screws from the Asycube Clean 230, as it is tested by Asyril during production to ensure its IP65 sealing. Ignoring this instruction will void the warranty and may compromise the waterproof integrity of the Asycube, leading to potential damage.

Sealing of the interface panel

Important

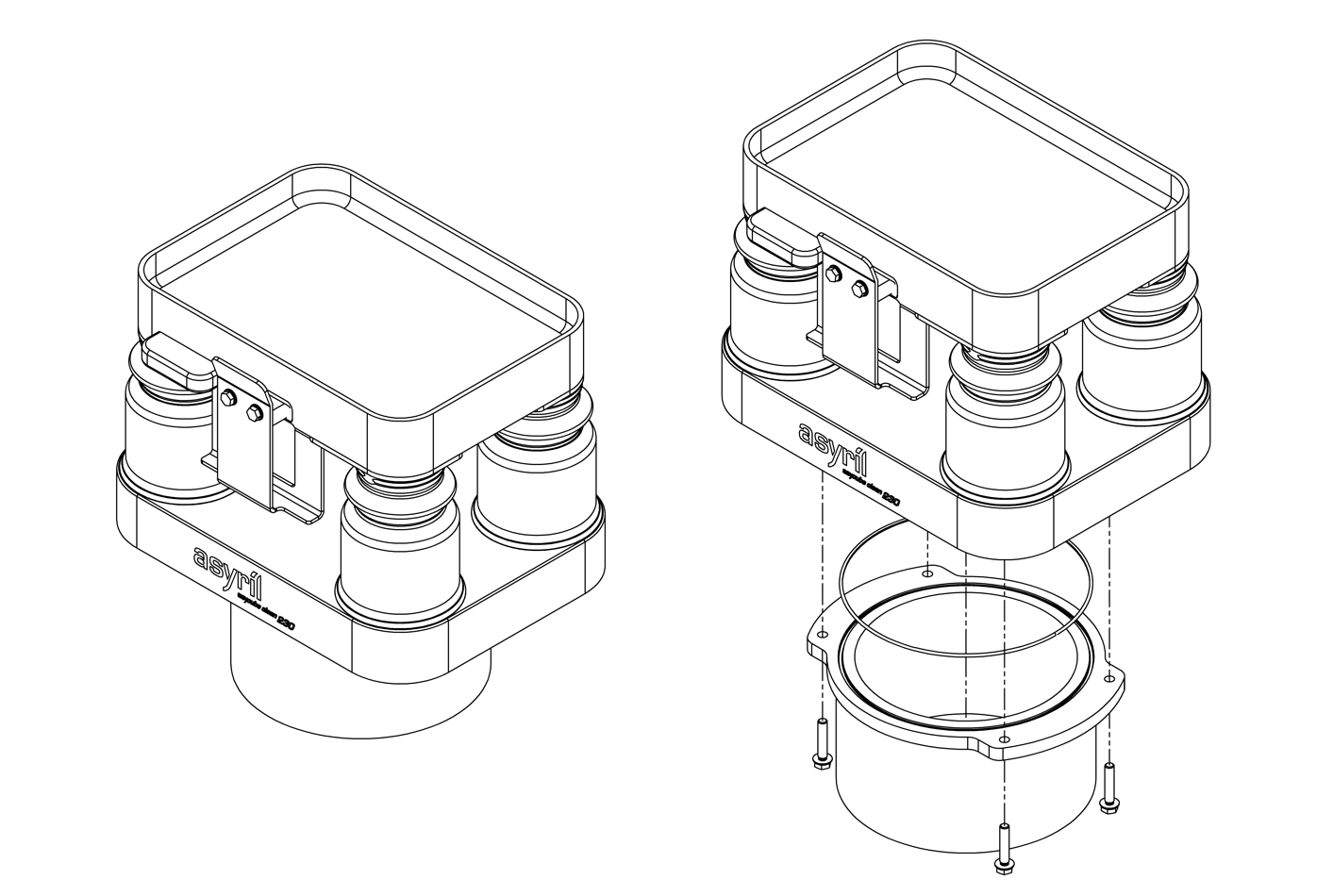

The electrical interface panel of the Asycube Clean 230 is not waterproof. To ensure optimal sealing, it is necessary to use a mounting column which must be custom-made by the integrator. The sealing is achieved by using an O-ring. The Fig. 21 illustrates an example.

Important

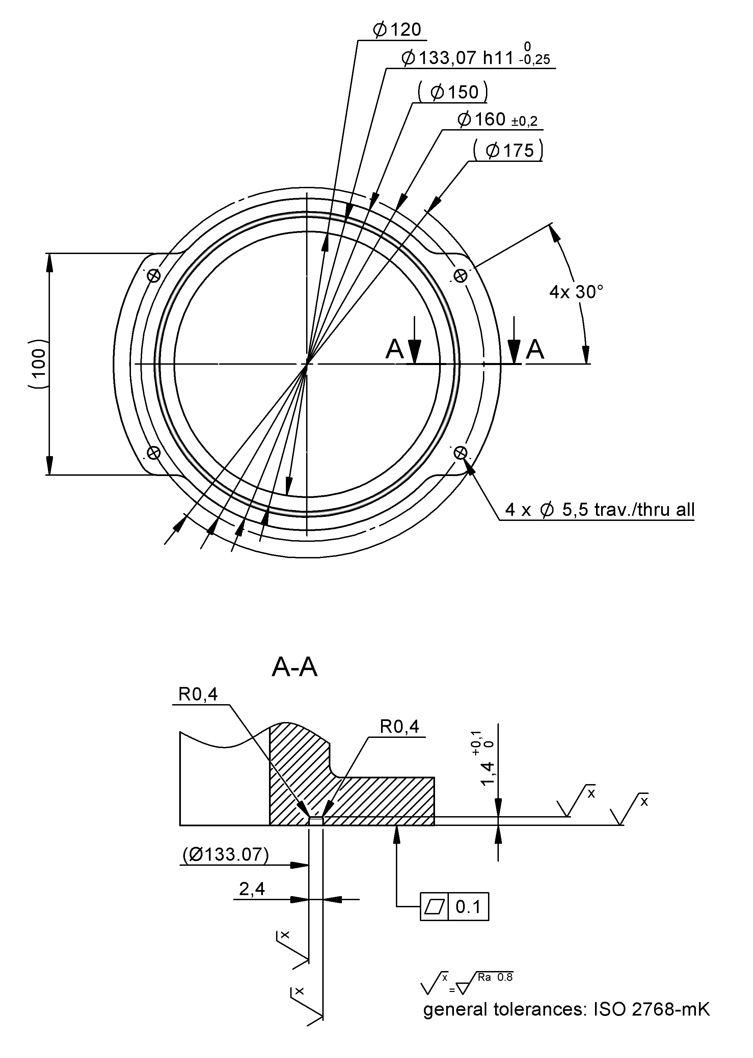

The drawings of Fig. 22 serve as an example of the design. Asyril is not responsible for any potential damage that may occur due to inadequate sealing at this interface, nor for the design or integration of the product.

Fig. 21 Asycube Clean 230 mounted on a column with its sealing interface

Fig. 22 Asycube Clean 230 - recommended sealing interface

The following O-ring references are suggested:

Reference |

Manufacturer |

Dimensions |

004157 |

Kubo |

ID=133.07mm x d2=1.78mm |

BS050S70FDA |

Eastern Seals |

ID=133.07mm x d2=1.78mm |

Fixation in the machine

The base plate on which the Asycube is mounted must be rigid and weigh at least 50 kg. If the rigidity of the base plate is insufficient, unwanted vibrations will be transmitted to adjacent systems, which may negatively affect the performance of the Asycube and neighboring systems.

If the adjacent components are very sensitive to vibrations, a complete decoupling can be done at the level of the machine’s chassis/structure by using suitable sealing elements (elastomer bellows). This integration is the responsibility of the integrator.

For more information, please contact our support team from our website.