Warning

You are reading an old version of this documentation. If you want up-to-date information, please have a look at 2025.11 .Holes

Holes are useful when cylindrical components are to be fed and presented upright.

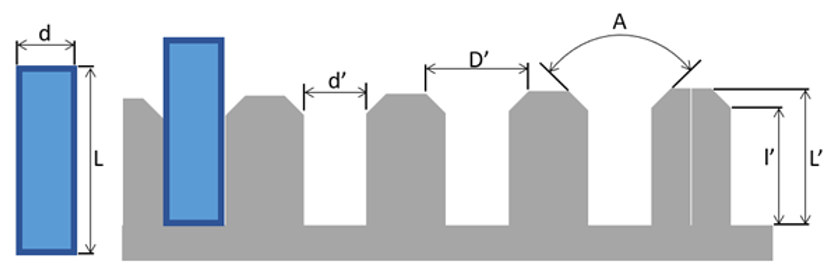

Fig. 45 Representation of a platform with holes

The diameter of the hole (d’) is the most important dimension of the plate. It is mandatory to have a large enough diameter to allow the part to straighten out once inside the hole. For parts up to 3.5mm of diameter, 0.05 mm is added to the maximum part diameter (d). However, for larger parts, with diameter larger than 3.5mm, as well as non-cylindrical parts (e.g. conical), a larger diameter is required.

The hole should be deep enough (l’) to allow the part to be guided along the walls if necessary. If the workpiece rests on the bottom, there is no need for a long guide.

It is preferable to guide the part at least on 1/3 of the height of the part (L), ideally ½, so that the piece stays as straight as possible.

Attention should also be paid to the residual height of the part above the plate (L’).

The chamfer (A) is essential to allow the part to fall into the hole. In most cases, the chamfer angle is 60°.

D’ |

d’ |

l’ |

A |

|

|---|---|---|---|---|

Asycube 50 |

> 0.5*L |

d + 0.05mm |

0.5*L |

60 |

Asycube 80 |

> 0.5*L |

d + 0.05mm |

0.5*L |

60 |

Asycube 240 |

> 0.5*L |

d + 0.1mm |

0.5*L |

60 |

Asycube 380 |

> 0.5*L |

d + 0.5mm |

0.5*L |

60 |

Asycube 530 |

> 0.5*L |

d + 1.0mm |

0.5*L |

60 |