Warning

You are reading an old version of this documentation. If you want up-to-date information, please have a look at 2025.11 .Plate

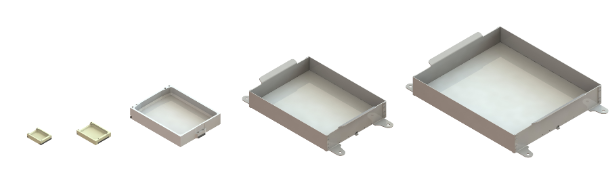

To transmit vibrations from the Asycube’s actuators to the parts, a platform is needed. The platform is fixed to the upper side of the Asycube. The platform is made of :

A frame: walls to contain the parts and avoid them to jump out of the Asycube.

A plastic diffusing plate: horizontal surface that diffuses light and on which parts are laying.

For Asycube 50, 80 and 240, the plate is made of one single part. The diffusing plate and the frame are manufactured in one piece. The overall dimensions of the platforms are listed here below:

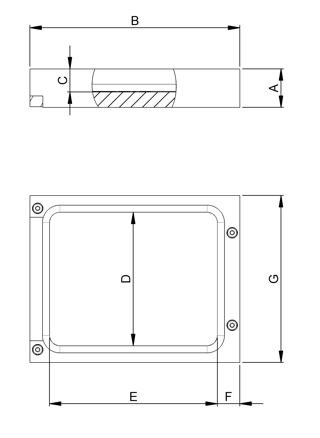

Fig. 33 Overall dimensions of platforms for Asycube 50 and Asycube 80

Asycube 50 |

Asycube 80 |

|

|---|---|---|

A |

14 |

15 |

B |

60 |

82 |

C |

8 |

9 |

D |

34 |

52 |

E |

45 |

65 |

F |

8 |

9 |

G |

46 |

65 |

For Asycube 50, 80 and 240, the platform is made of one single part. The diffusing plate and the frame are manufactured in one piece. The overall dimensions of the platforms are listed here below

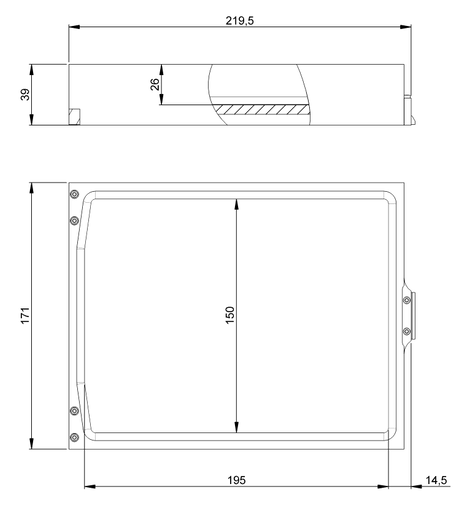

Fig. 34 Overall dimensions of platforms for Asycube 240

Asycube 240 |

|

|---|---|

A |

39 |

B |

219.5 |

C |

26 |

D |

150 |

E |

195 |

F |

14.5 |

G |

171 |

H |

0.2 |

M |

0.5 |

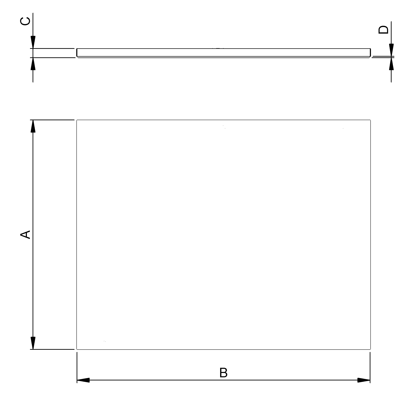

For larger Asycube, 380 and 530, the diffusing plate and the frame are manufactured separately. The frame needs to be metallic to guarantee enough rigidity. The overall dimensions of the plates are listed here below :

Fig. 35 Overall dimensions of platforms for Asycube 380 and Asycube 530

Platform Asycube 380 |

Platform Asycube 530 |

|

|---|---|---|

A |

252.8 ± 0.5 mm |

369.8 ± 0.5 mm |

B |

323.8 ± 0.5 mm |

426.8 ± 0.5 mm |

C |

10 mm |

10 mm |

D |

1.5x45° (4x) |

1.5x45° (4x) |

Tip

Depending on your application needs and the part geometry, the material, geometry and design of the diffusing plate can be adapted :

If the natural resting position corresponds to the picking orientation, Flat plates is recommended.

To reduce stabilization time after vibrations, Anti-roll plates can be used.

If parts tend to stick to the plate because of contact surface, using Anti-stick plates can improve and accelerate parts displacements.

If the natural resting position of the parts does not match the desired picking orientation, Custom platform with holes, pockets or grooves can be designed in order to reorient the parts correctly.