Warning

You are reading an old version of this documentation. If you want up-to-date information, please have a look at 2025.11 .Integration examples

Standard integration

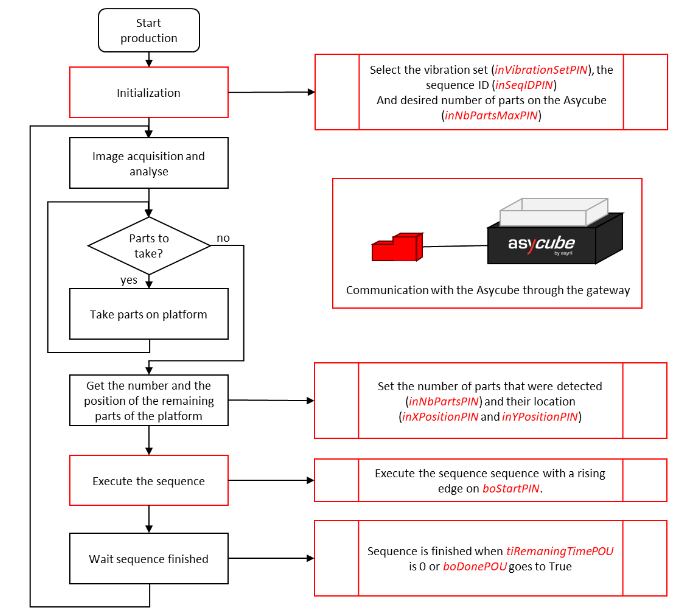

You find here a typical Asycube integration example (Fig. 187). For this standard integration, you will need one single AO_Execute_Sequence block per Asycube.

When you start the production, a first image analysis will be done and, as long as parts OK to be picked are available, their coordinates will be sent to the robot until the last one is picked.

When no more parts are available, you will trigger the execution of a vibration sequences knowing how many parts are on

the feeder and the position of their center of mass (inXPosPIN and inYPosPIN values corresponds to 100x the

values described in the coordinate system for the center of mass).

Tip

We recommend triggering the backlight using the dedicated digital input. Should you not have this possibility,

the input boBacklightPIN can be used to control it.

Fig. 187 Standard implementation example

Other integration

If the standard integration does not fit to your application, other AOs can be used. Nevertheless, we strongly recommend working like in the standard example above. All AOs are described in Add-on instructions description.