Avertissement

Vous lisez une ancienne version de cette documentation. Si vous souhaitez obtenir des informations actualisées, veuillez consulter 2025.11 .Standard hoppers

The standard hoppers sold by Asyril include:

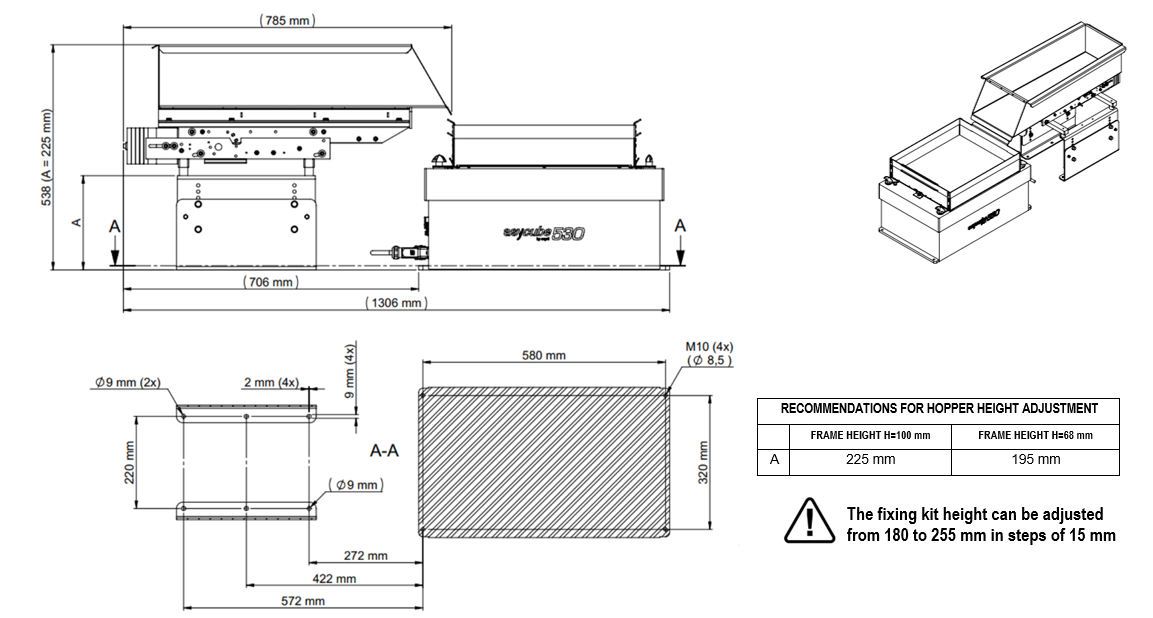

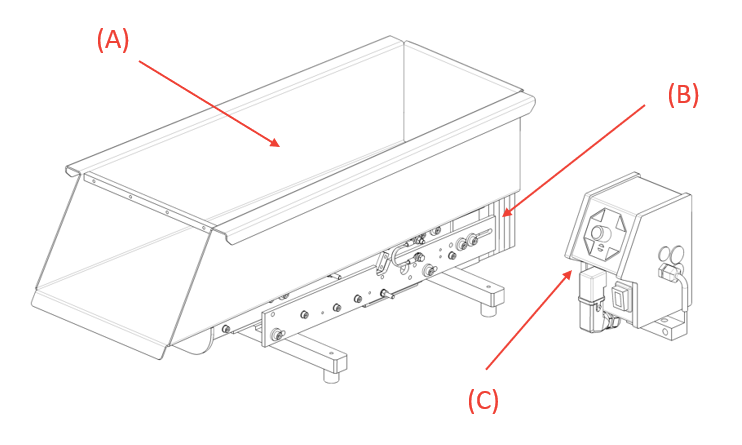

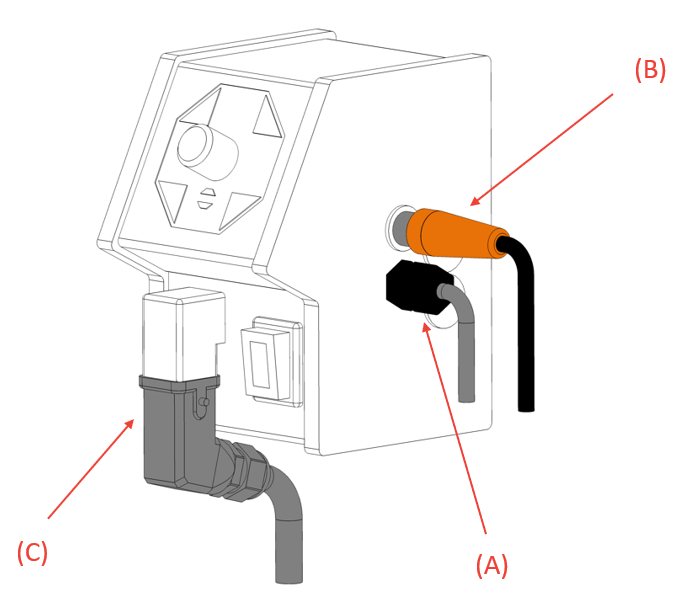

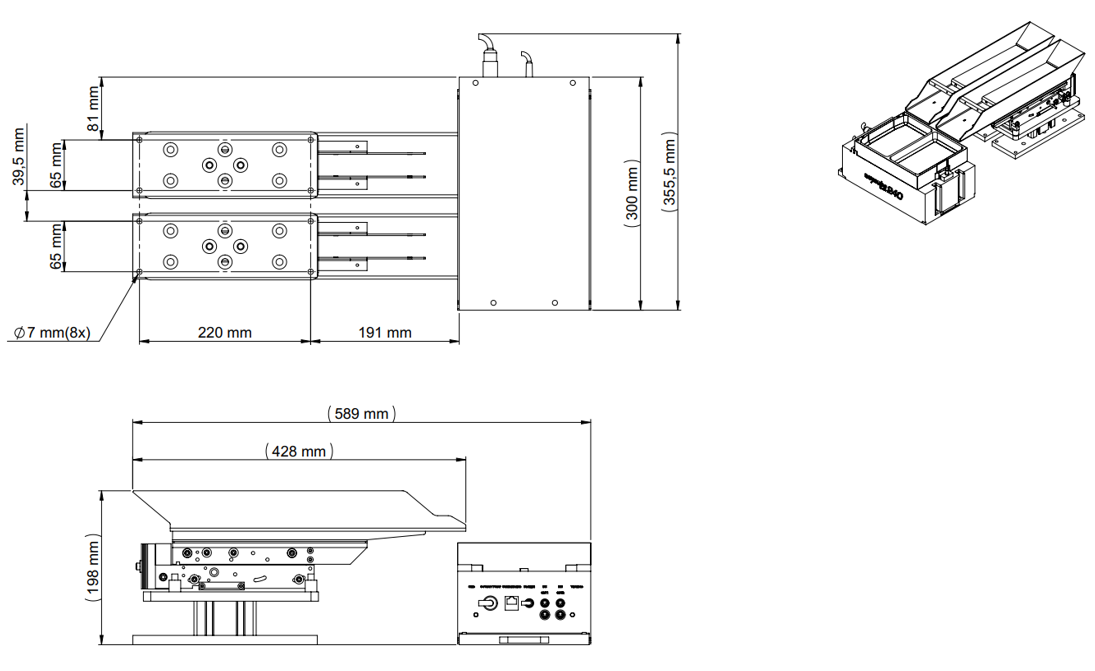

Fig. 56 Standard hoppers for Asycube 240, 380 and 530, including control unit

(A) The container (see Interfaces mécaniques) receiving the parts. Depending on the size of the parts to be fed and the required machine autonomy, different sizes may be used (1L, 2L, 3L, 10L or 15L). These containers are in stainless steel Inox 1.4301.

(B) The linear vibrator (see Interfaces mécaniques) that moves the parts on the container to feed the Asycube.

(C) The Unité de contrôle used to adjust the hopper vibration amplitude.

A set of three different cables is also included (see Interfaces électriques).

Instructions de démarrage rapide

Remove contents from box:

1x hopper unit

1x hopper control unit

3x cables (mains power cable, actuator power cable, digital control cable)

Install and mount the hopper, see more details in Montage.

Install the hopper control unit, see more details in Montage.

Connect the digital control cable from the Asycube digital output port to the hopper control unit.

Connect the actuator power cable from the hopper to the hopper control unit.

Connect to mains, either 115V or 230V and 50Hz or 60Hz.

Important

The input voltage and frequency must match the voltage and frequency of the hopper vibrating mechanism. If this is not respected, the hopper could be irreversibly damaged.

Turn the hopper control unit ON/OFF switch to ON.

Enable the digital output of the Asycube.

Confirm that the hopper is vibrating.

Adjust the vibration level as needed with the potentiometer (0-100%) on the hopper control unit.

Interfaces électriques

Schéma de câblage

The hopper is supplied with the controller and cables ready to be installed. The Tableau 11 gives the current ratings for the different type of hoppers.

Important

The input voltage and frequency must match the voltage and frequency of the hopper vibrating mechanism. If this is not respected, the hopper could be irreversibly damaged.

Hopper type |

AC characteristics |

Actuator nominal current |

Recommended rated current |

|---|---|---|---|

Trémie 1L |

115VAC/50 or 60Hz |

0.17A |

1A 1 |

230VAC/50 or 60Hz |

0.08A |

1A 1 |

|

2L/3L Hopper |

115VAC/50 or 60Hz |

1.32A |

2A 1 |

230VAC/50 or 60Hz |

0.6A |

2A 1 |

|

10L/15L Hopper |

115VAC/50 or 60Hz |

1.32A |

2A 1 |

230VAC/50 or 60Hz |

0.6A |

2A 1 |

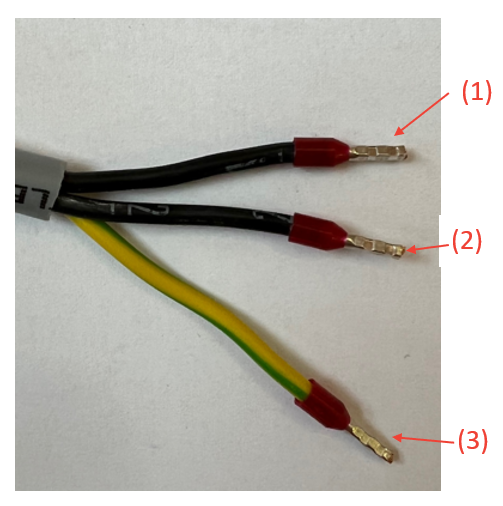

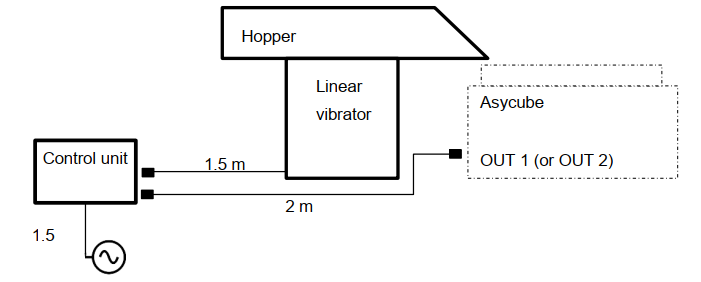

The cables length supplied with the hopper and the wiring diagram are shown in Fig. 57. The signal polarity of the controller cable is detailed in Tableau 12.

Fig. 57 Wiring diagram and cables length

Numéro |

Signal |

Fils internes |

Câble de l’unité de contrôle de la trémie |

|---|---|---|---|

1 |

L |

Identifié par un 1 ou brun |

|

2 |

N |

Identifié par un 2 ou bleu |

|

3 |

PE |

Mise à terre (vert/jaune) |

Wiring and pairing table

The hoppers wiring depends on the number of hoppers and either you are using EYE+ or not.

With EYE+ |

Without EYE+ |

|

|---|---|---|

1 hopper |

Asycube I/O Cable |

Asycube I/O Cable |

2 hopper |

Asycube I/O Cable |

Asycube I/O Cable |

3 hopper |

EYE+ GPIO Cable |

1 |

4 hopper |

EYE+ GPIO Cable |

1 |

Unité de contrôle

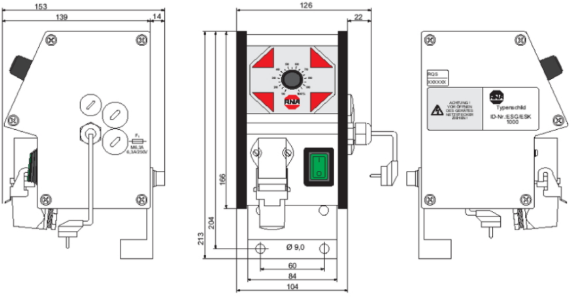

Fig. 58 Unité de contrôle

(A) Mains power cable: connects the control unit to the mains supply.

(B) Digital control cable: connects the control unit to the Asycube.

(C) Actuator power cable: connects the control unit to the linear vibrator.

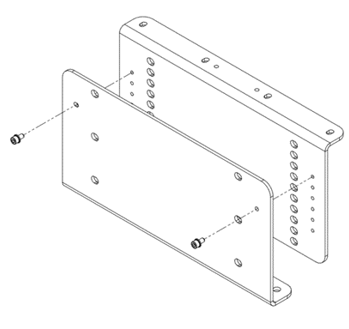

The dimensions of the control unit including the supplied mounting bracket are detailed in Fig. 59.

Fig. 59 Unité de contrôle

Remarque

Position the control unit so that you can reach the potentiometer.

Interfaces mécaniques

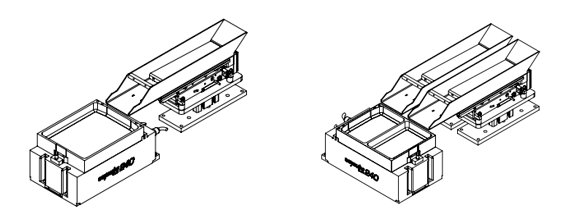

The different variants of hoppers (1L, 2L, 3L, 10L and 15L) can be mounted on the back or on the side of the Asycube. This enables applications such as multi-feeding where multiple different parts are being fed onto the same Asycube simultaneously via multiple hoppers, as illustrated in Fig. 60.

Fig. 60 Illustration of single part feeding versus multi-feeding with two parts

Remarque

With multi-feeding applications, since both parts will share the same vibration settings, attention must be paid to how parts are combined. A very heavy and large part combined with a light and small one might not give satisfying results. Since many factors can affect the vibration characteristics, we strongly advise you to perform some preliminary tests first.

The table below summarizes which hopper size can be used in conjunction with which Asycube with single part feeding or multi-feeding applications:

Trémie 1L |

Trémie 2L |

Trémie 3L |

Trémie 10L |

Trémie 15L |

|

|---|---|---|---|---|---|

Asycube 240 |

yes |

yes |

yes |

N/A |

N/A |

Asycube 380 |

yes |

yes |

yes |

yes |

yes 1 |

Asycube 530 |

yes |

yes |

yes |

yes |

yes |

Trémie 1L |

Trémie 2L |

Trémie 3L |

Trémie 10L |

Trémie 15L |

|

|---|---|---|---|---|---|

Asycube 240 |

yes |

N/A |

N/A |

N/A |

N/A |

Asycube 380 |

yes |

yes |

yes |

yes 2 |

N/A |

Asycube 530 |

yes |

yes |

yes |

yes 2 |

yes 2 |

Remarque

Les trémies 2L et 3L sont livrées avec des pieds de montage qui peuvent être fixés à la base de la machine directement à la bonne hauteur pour un Asycube 240 à l’aide de quatre vis M8x20.

Remarque

When pairing 1L, 2L, 3L, 10L and 15L hoppers with Asycube 380 and Asycube 530, the optional modular hopper fixing kit allows the hopper to be mounted at the ideal height.

Remarque

When two hoppers can be mounted on the same long side of the Asycube, a multi-feeding application with up to 4 parts can also be considered by mounting 4 hoppers symmetrically. If your application requires a configuration with more than two hoppers, please visit the multi-feeding section in EYE+ documentation or contact our support team from our website.

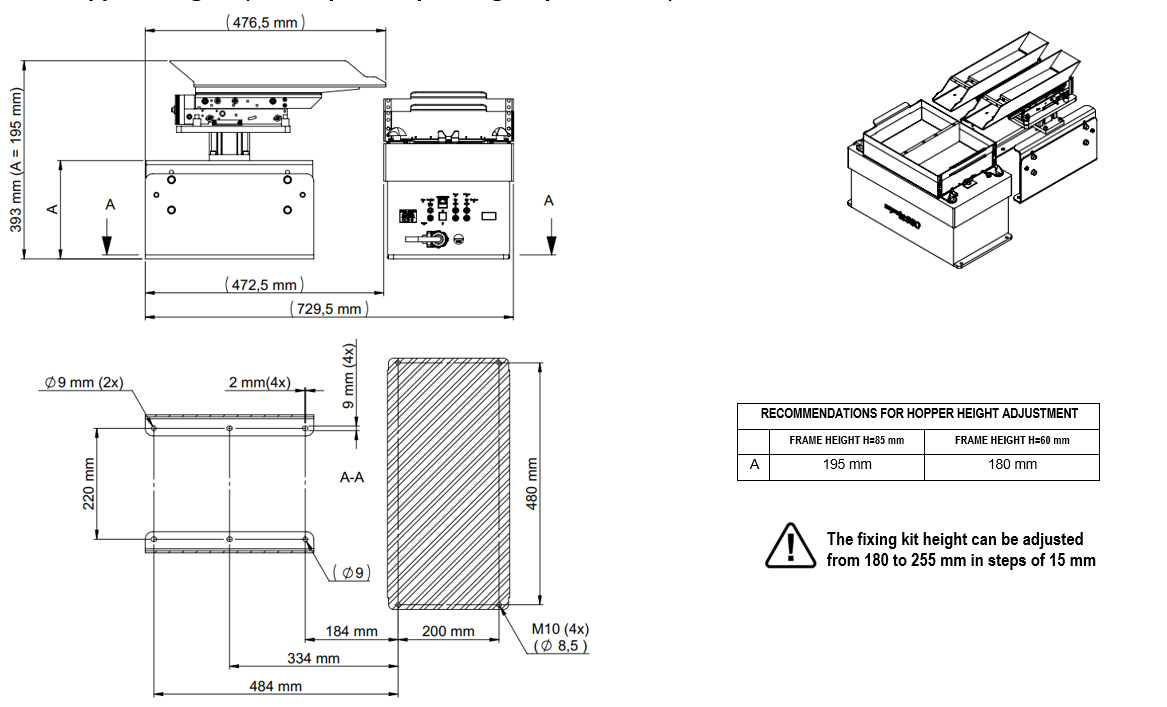

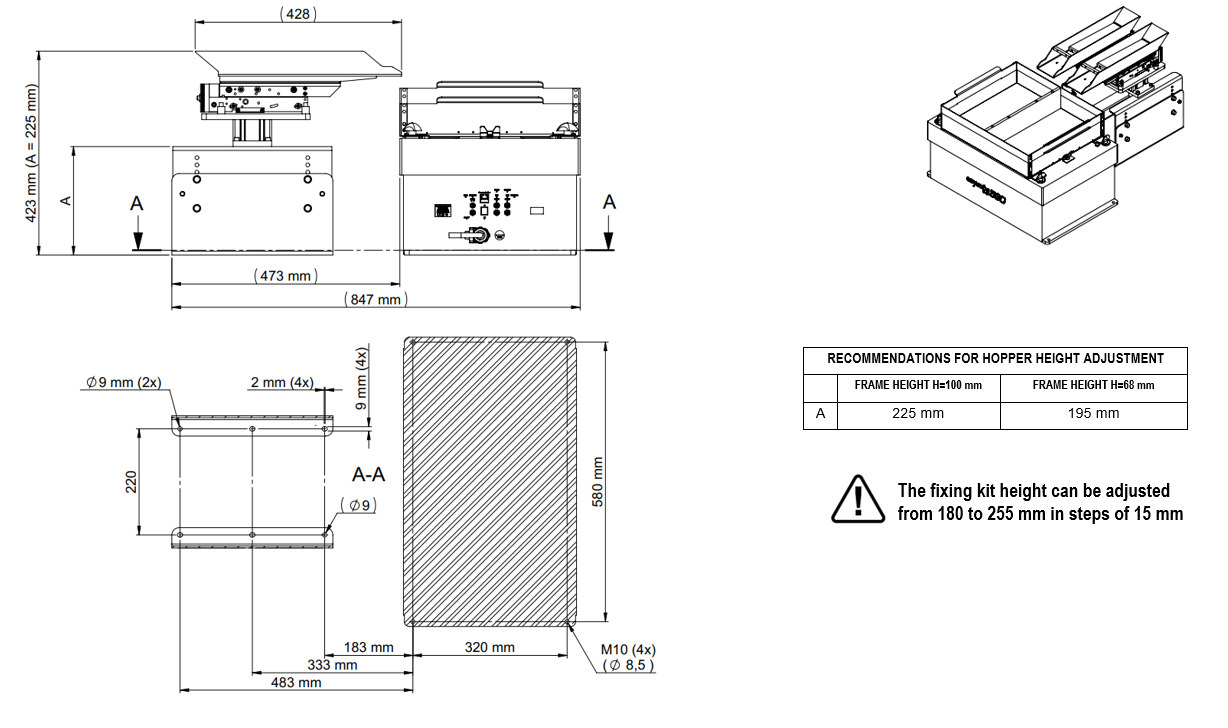

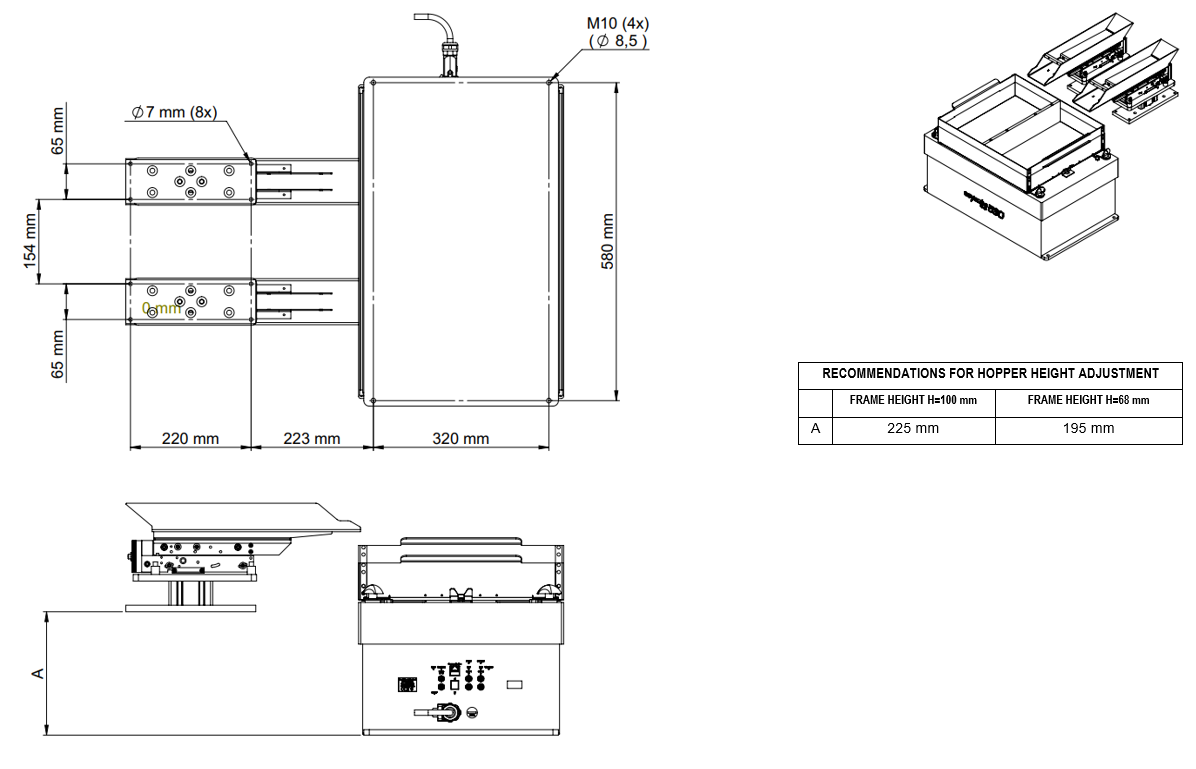

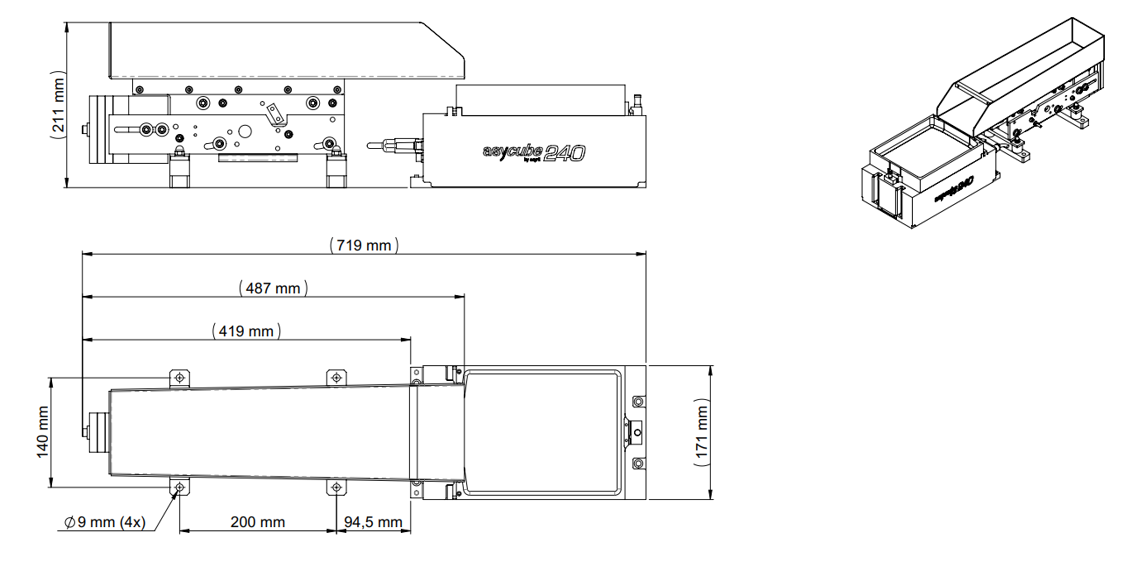

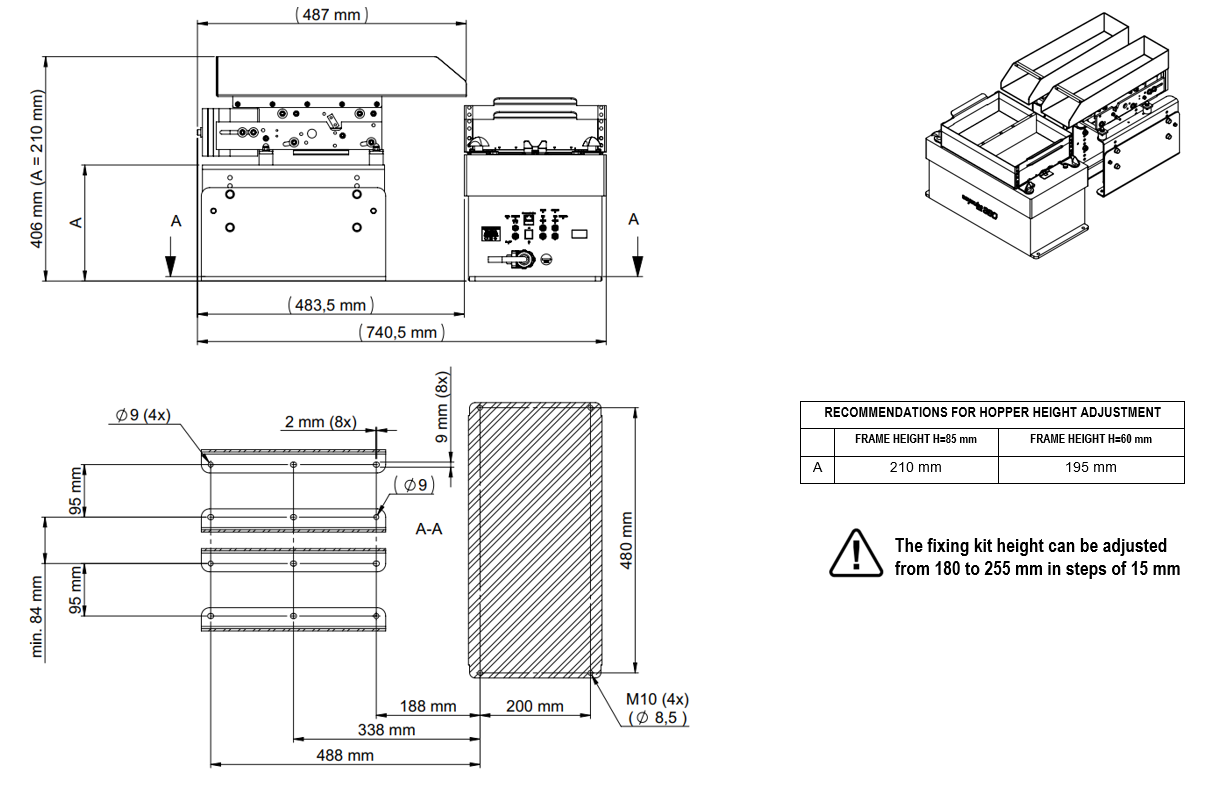

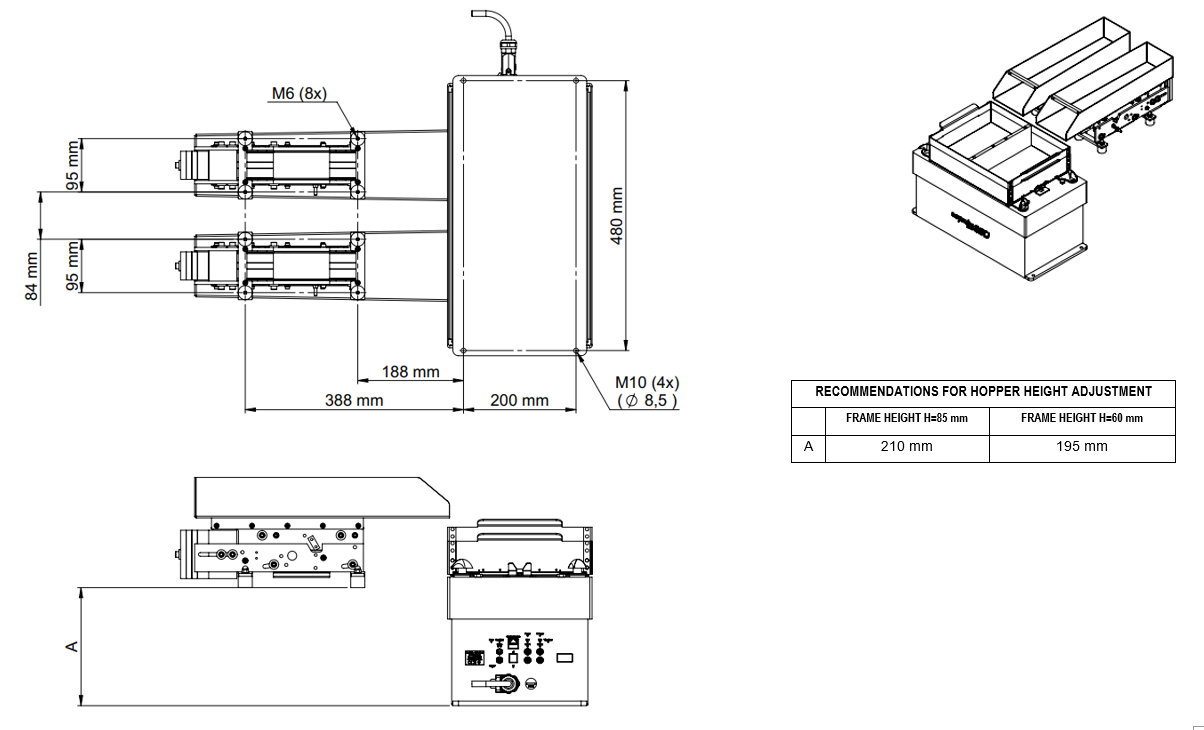

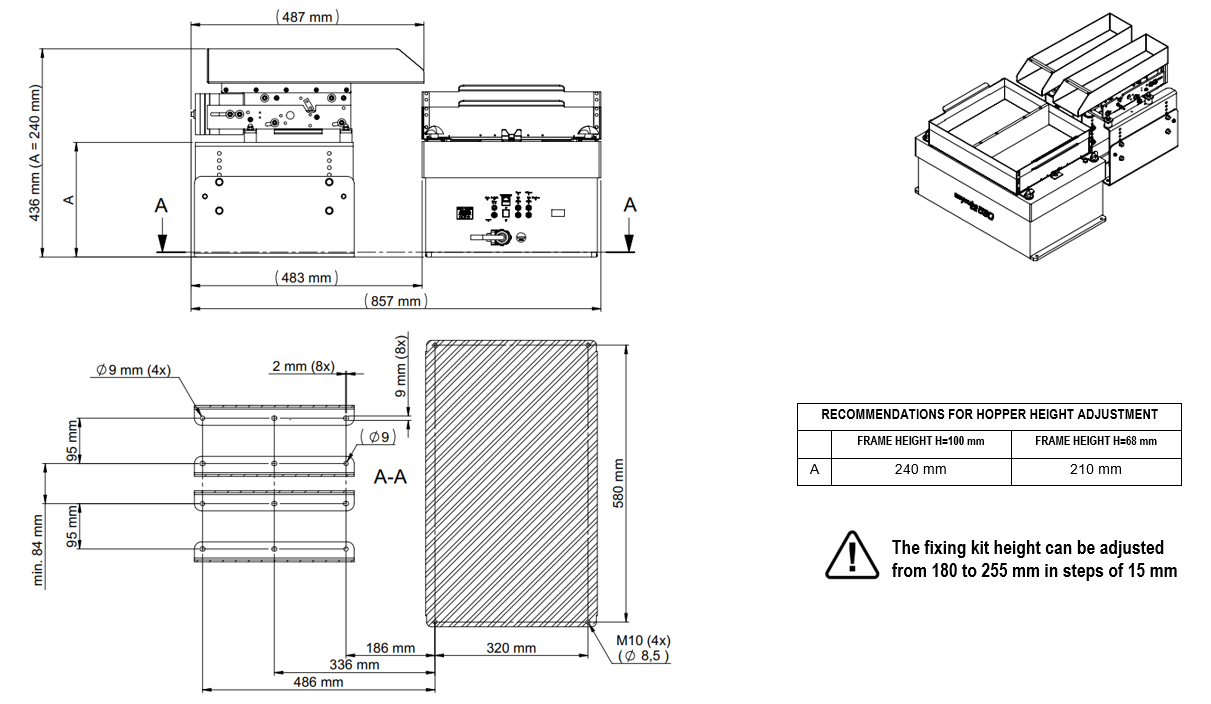

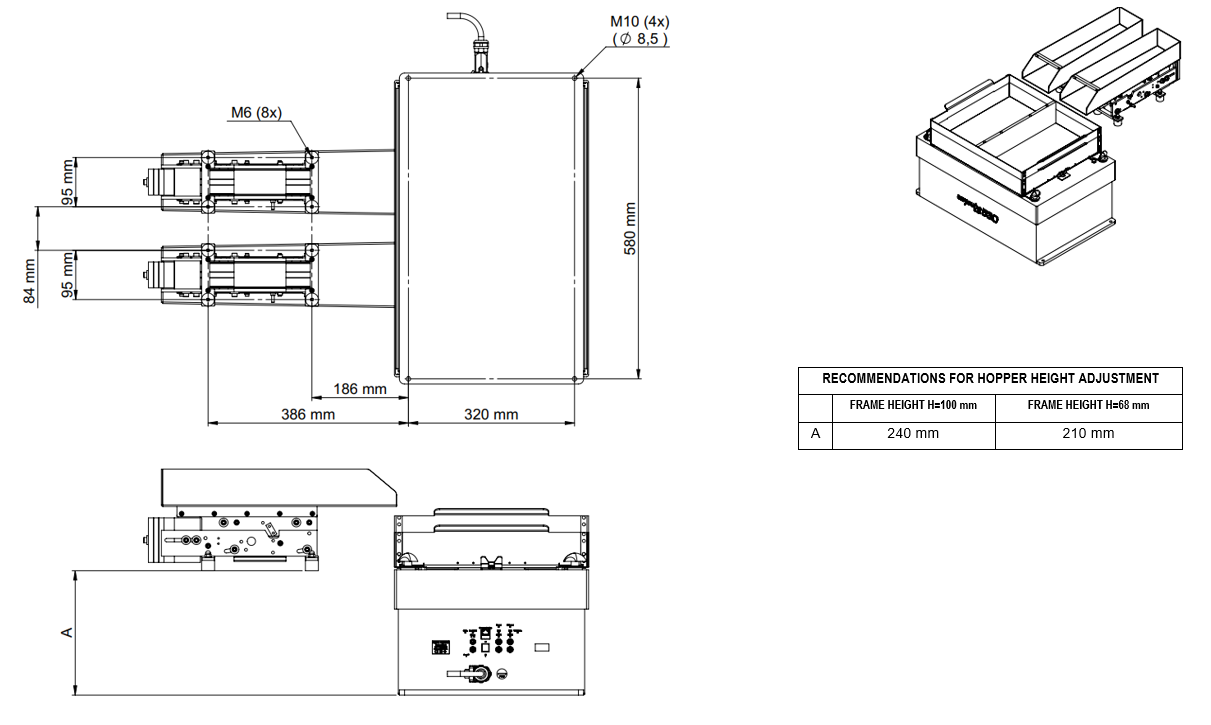

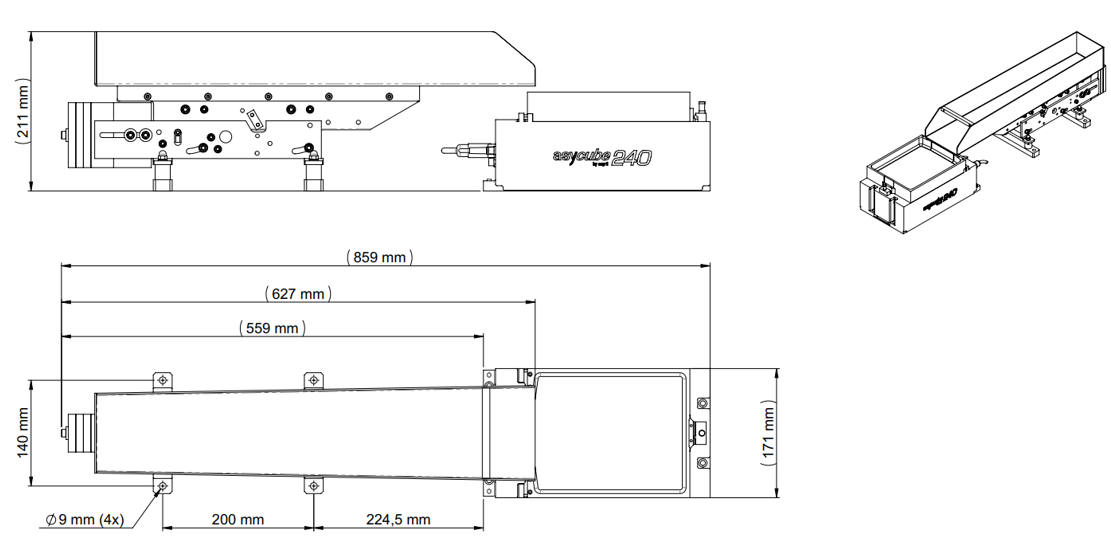

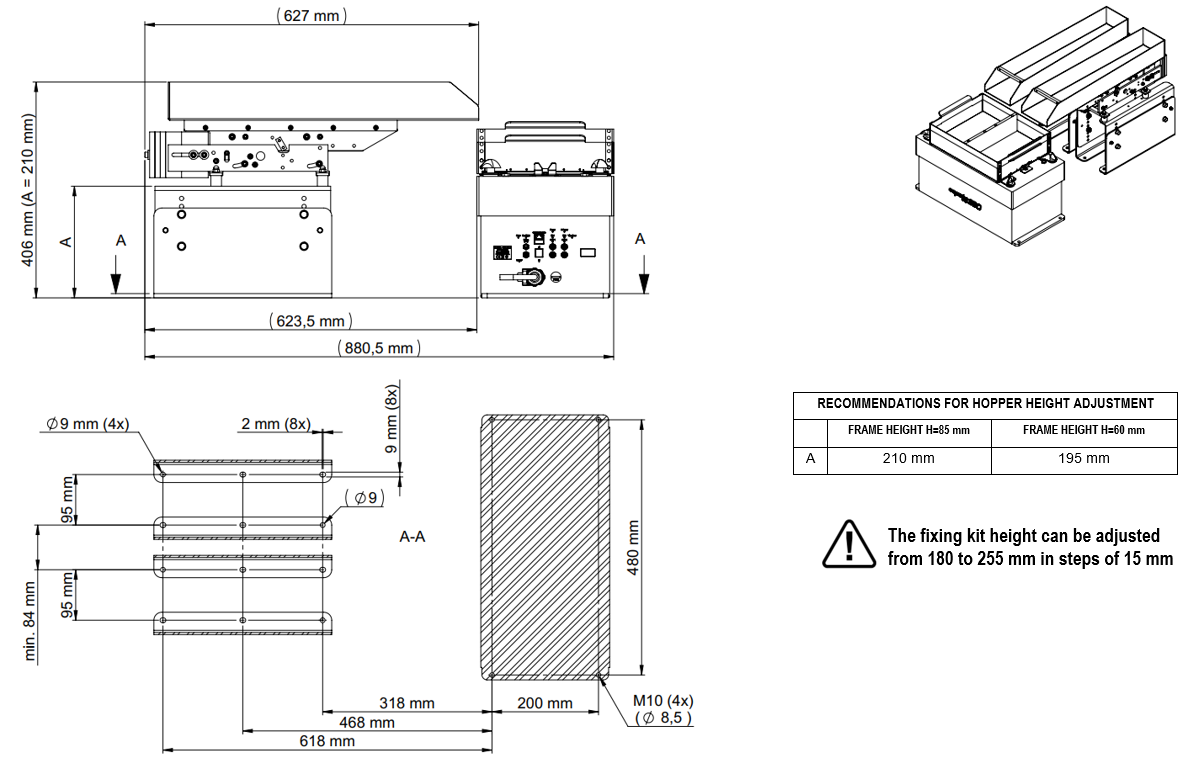

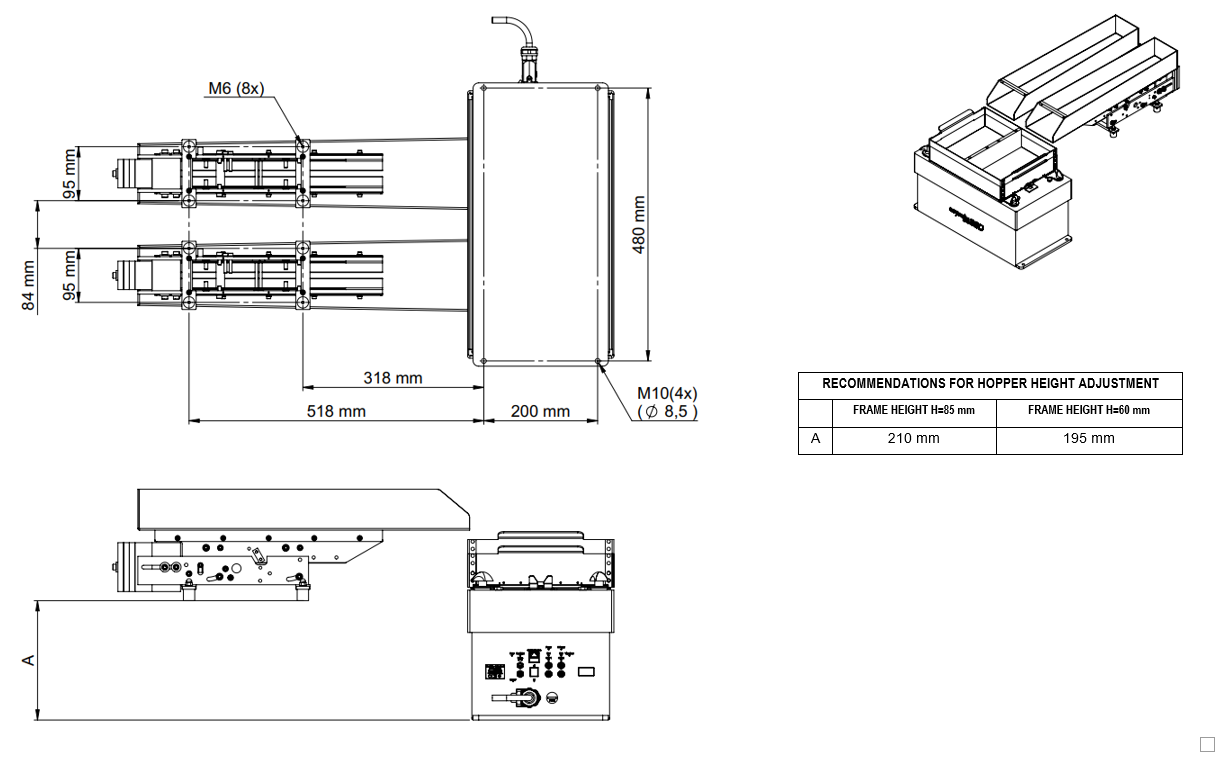

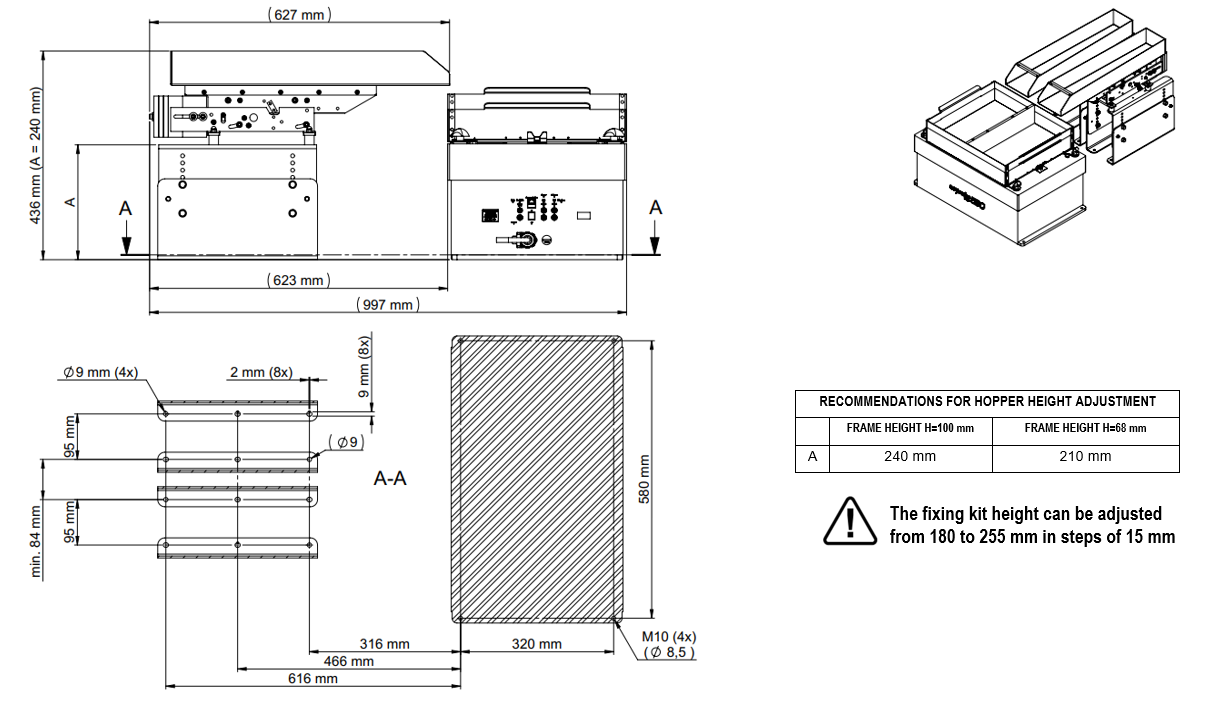

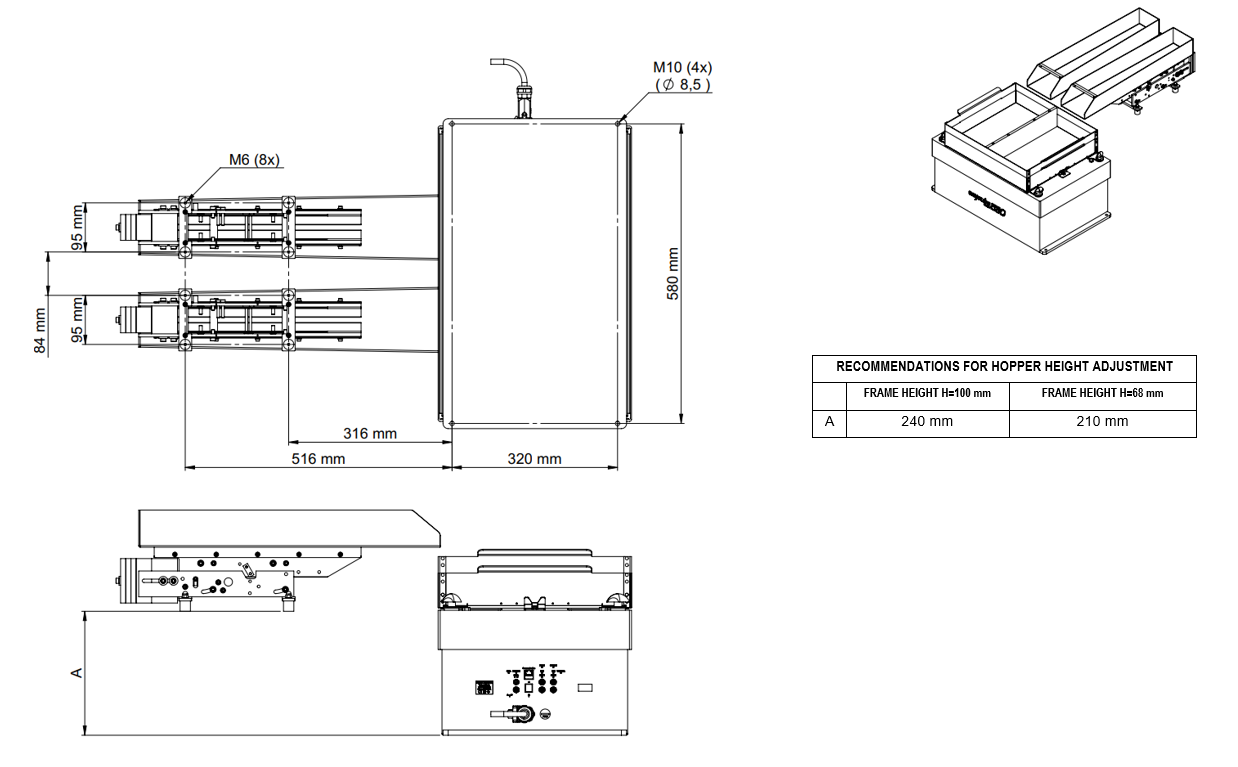

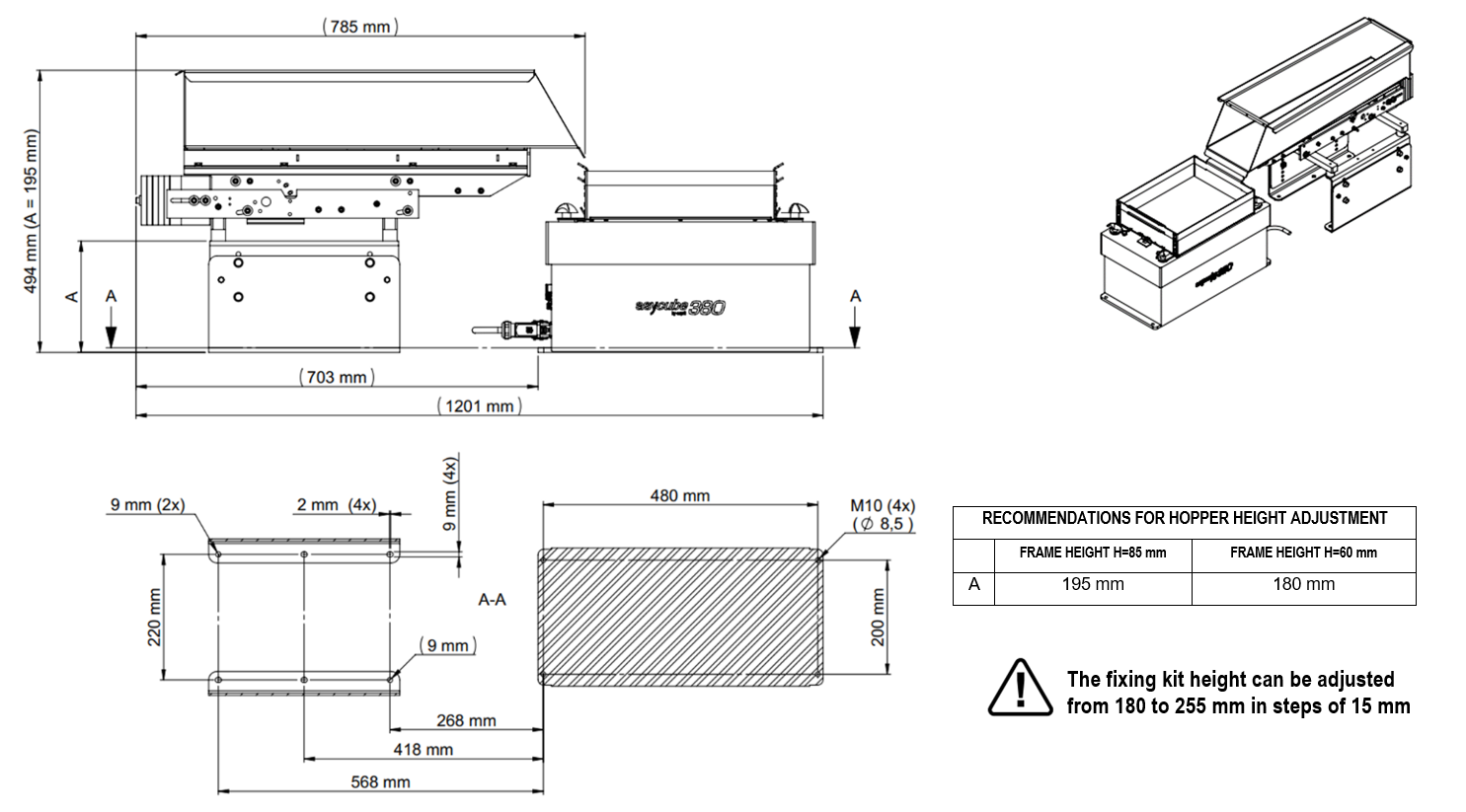

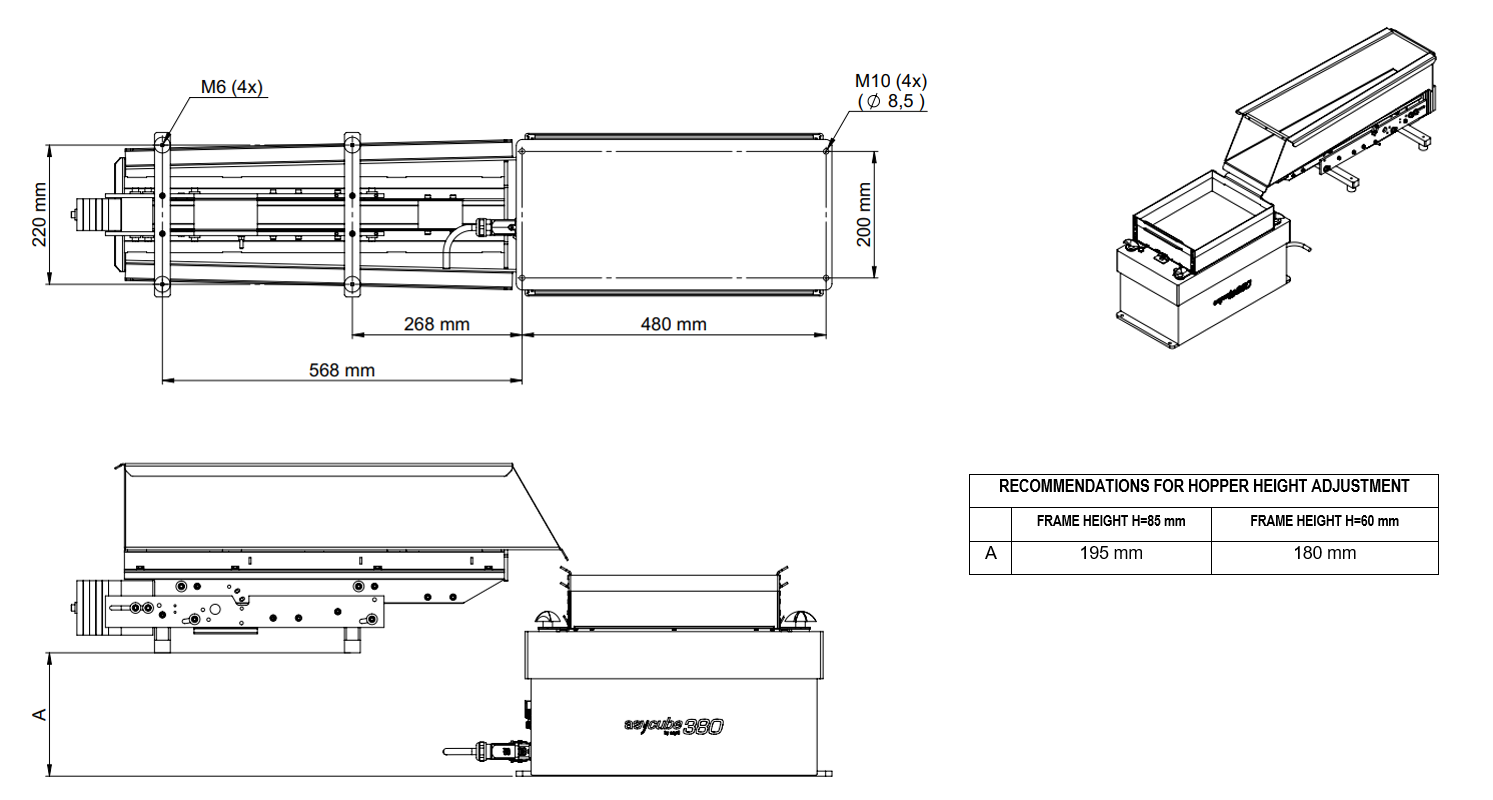

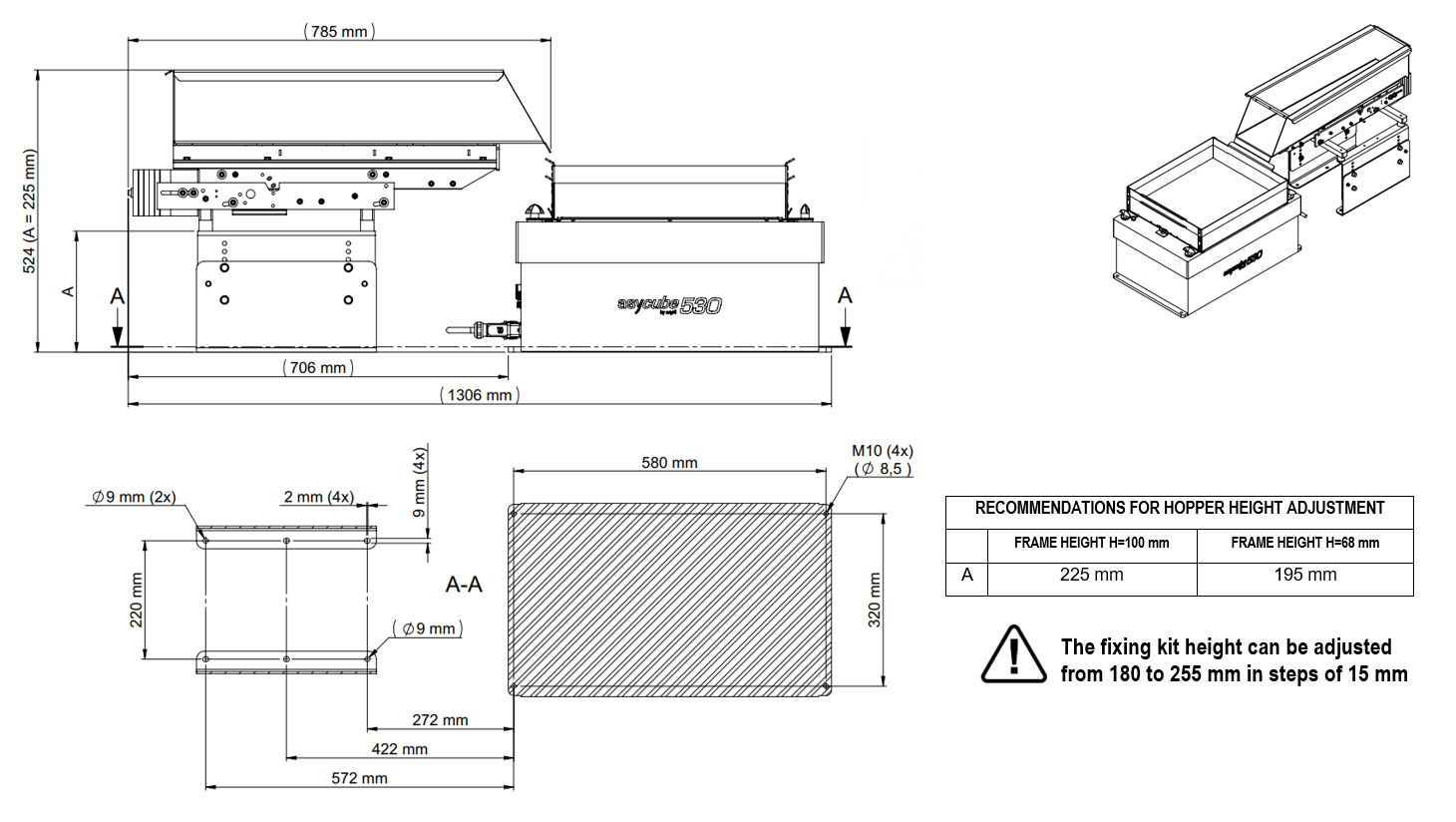

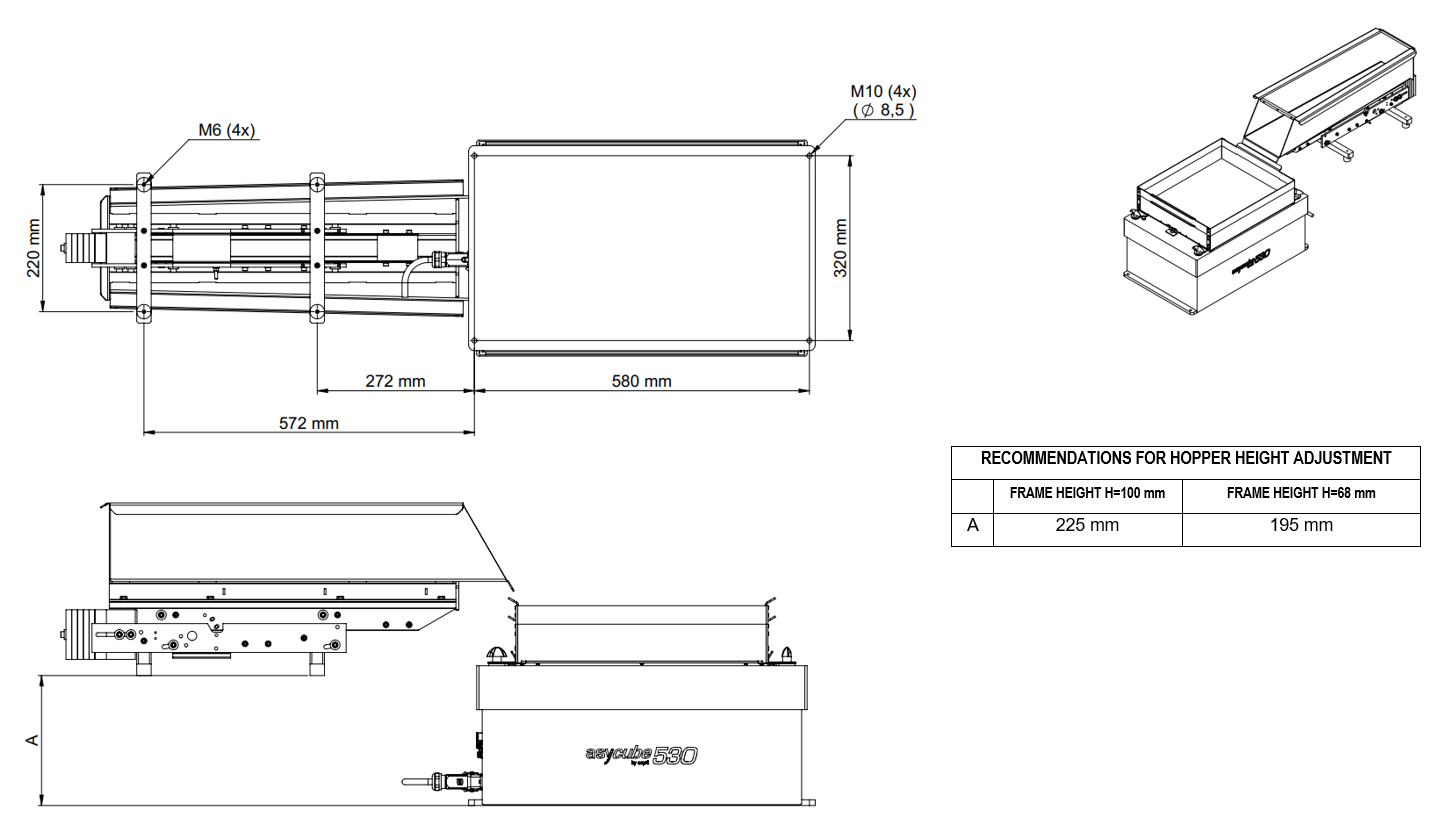

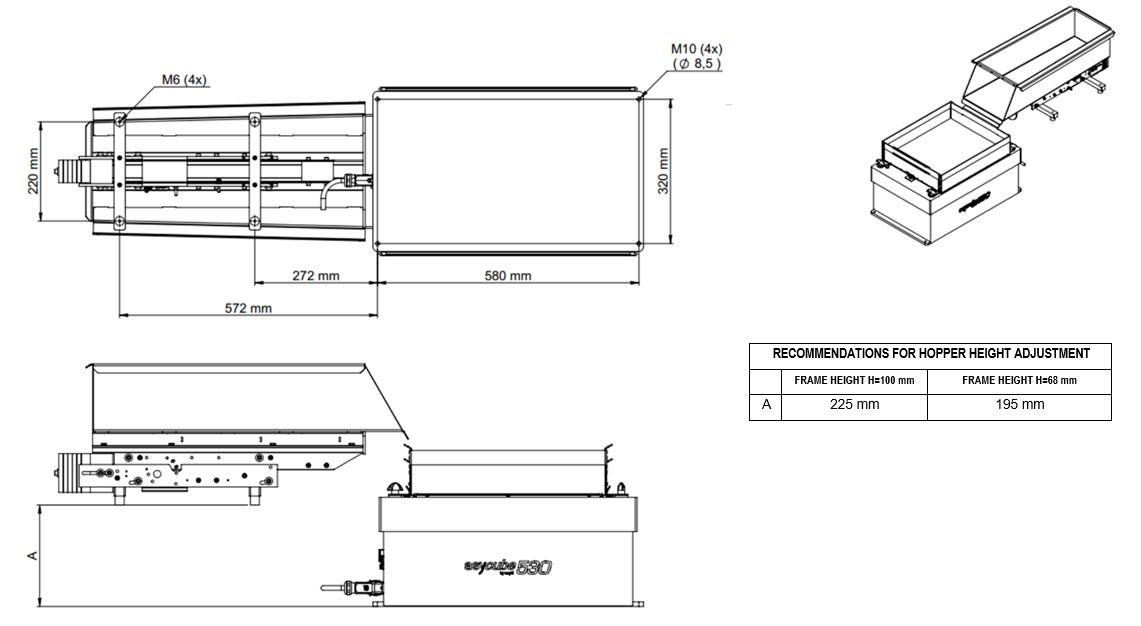

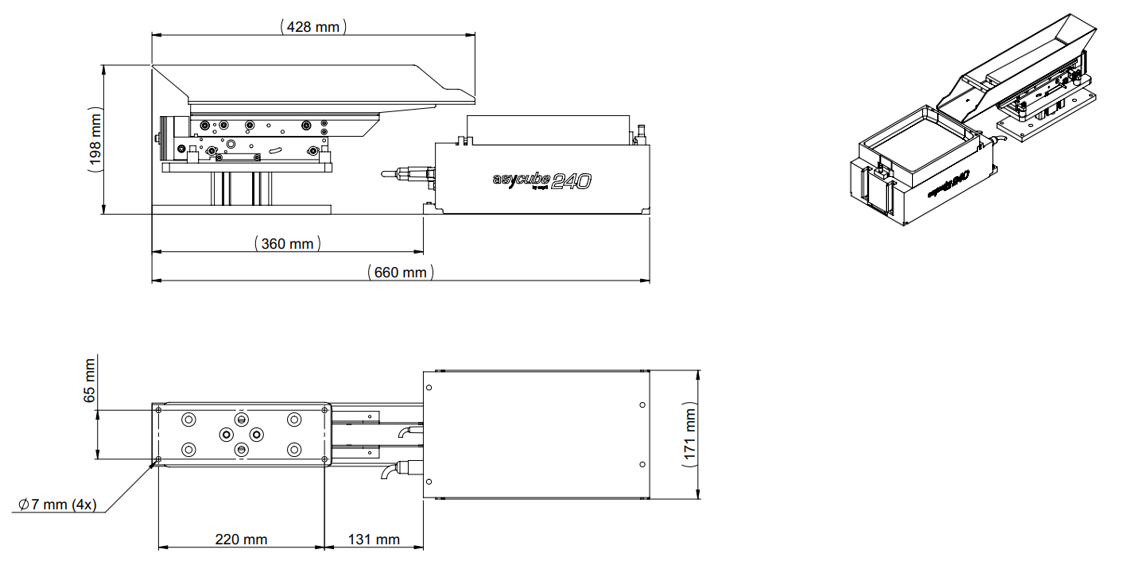

The following diagrams represent at which height the different hoppers shall be mounted and the position of the holes to fix the hopper to the machine base plate for single part feeding and multi-feeding with two parts.

Trémie de 1 L

Fig. 61 Single part feeding: Asycube 240 with 1 L hopper

Fig. 62 Multi-feeding with two parts: Asycube 240 with two 1 L hoppers

Trémie de 2 L

Interfaces mécaniques Trémie de 3 L

Interfaces mécaniques Trémie de 10 L

Interfaces mécaniques Trémie de 15 L

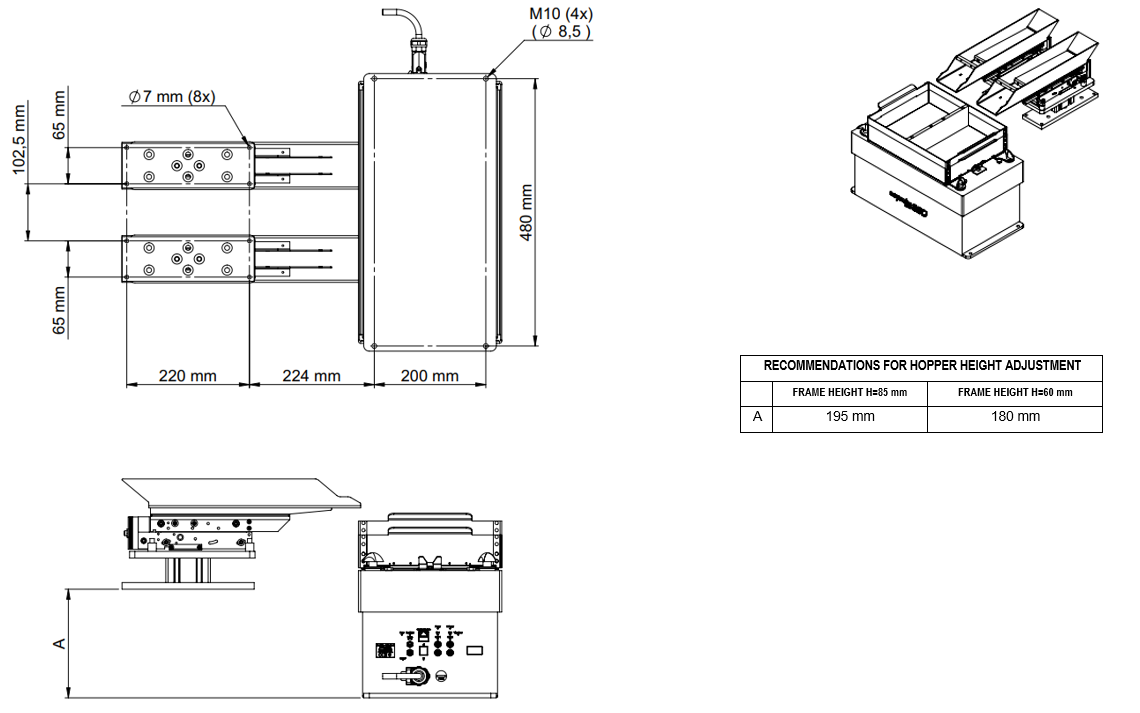

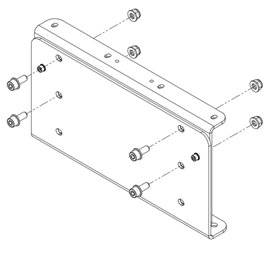

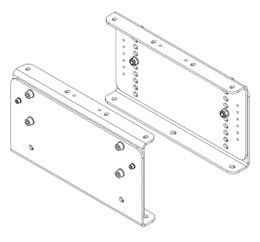

Kit de fixation modulaire

Conseil

Cette section ne concerne que les Asycubes 380/530.

Le kit de fixation modulaire permet de positionner la trémie à une hauteur parfaitement adaptée à aux Asycubes 380/530. Les instructions de montage sont expliquées ci-dessous :

Étape 1

Choisissez la hauteur de fixation et fixez la première moitié avec 2 vis M5.

Remarque

La hauteur du kit de fixation peut être réglée de 180 à 255 mm par pas de 15 mm.

Étape 2

Sécurisez en fixant les 4 vis M8 avec écrous.

Étape 3

Répétez les étapes 1 et 2 pour la seconde moitié.

Étape 4

Fixez le kit de fixation modulaire sur la plateforme de base de la machine, puis fixez la trémie sur le kit de fixation.